XL-5309

SYNTHETIC EXTREME PRESSURE CUTTING AND GRINDING

FLUID

XL-5309 is a high performance, oil-rejecting synthetic fluid formulated for the most severe

steel and aluminum applications. XL-5309 is

designed to outperform EP-fortified soluble oils and semi-synthetics in most

operations. XL-5309 contains

no chlorinated,

sulfurized, or phosphorous-containing additives. XL-5309 is

formulated to reject tramp oil contamination by rendering the fluid

non-compatible with such materials. CHARACTERISTICS:

- Low Foaming (from very

soft to hard water) - Excellent sump life

- Quick tramp oil

rejection - Long lasting

| APPLICATIONS and DILUTIONS | Dilution Levels |

|---|---|

| Blanchard / Double Disc | 4:1 – 2:1 |

| Severe Grinding | 4:1 – 2:1 |

| Heavy Duty Machining | 2:1 – 1:1 |

| TYPICAL PROPERTIES | |

|---|---|

| Appearance | Clear Yellow |

| Specific Gravity | 1.0 |

| pH | 8.8 |

| CNC DRILLING AND TAPPING EVALUATION: | ||

| Material | 1018 Cold Rolled Steel | |

| Size of Plate | 6” x 4” x 0.5” | |

| Tooling | #25 (0.1495) HSS Steel | |

| DRILLING | TAPPING | |

| Speed | 2000 RPM | 394 RPM |

| Feed | 10.0 IPM | 15.6 IPM |

| Maximum Number of Holes | 405 | 405 |

| XL-5309 Concentration | 50% | 100% |

| DRILLING | |

|---|---|

| Number of Holes |

Tool Wear (inches) |

| 60 | 0.0007 |

| 120 | 0.0010 |

| 180 | 0.0012 |

| 240 | 0.0014 |

| 300 | 0.0015 |

| 360 | 0.0016 |

| 405 | 0.0019 |

|

TAPPING |

||

|---|---|---|

| Maximum Number of Holes | 405 | |

| Number of holes tapped | 405 | |

| Average wear (inches) | 0.0032 | |

| Surface Condition | Good | |

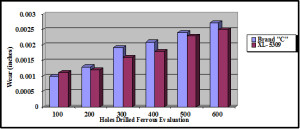

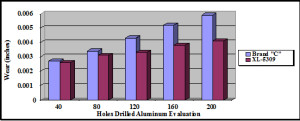

| Ferrous Evaluation | Aluminum Evaluation | |

|---|---|---|

Material |

1018 Cold Rolled Steel | 356T-6 Cast Aluminum |

Size of Plate |

8” x 10” x 1” | 4” x 6” x ¾ “ |

Tooling |

¼” HSS Steel Drill | #7 HSS Steel Drill |

Speed (RPM) |

1300 | 2800 |

Feed (IPM) |

7.0 | 14.0 |

Maximum Number of Holes |

600 | 2000 |

XL-5309 Dilution |

2:1 | 1:1 |

0 people have added this product to their cart

CategoriesGLASS & METAL WORK